Industry 4.0 goes beyond automation — it’s about creating a fully connected, data‑driven, and adaptive manufacturing ecosystem. At TreadBinary, we bridge the gap between your physical assets and digital intelligence through IIoT (Industrial Internet of Things) integration, cloud‑based manufacturing analytics, and seamless ERP/MES connectivity.

We start with an in‑depth assessment of your plant operations, identifying bottlenecks, data gaps, and integration opportunities. From there, we design a tailored solution that delivers real‑time machine monitoring, process automation, and AI/ML‑powered insights for faster, more accurate decision‑making. The outcome: reduced waste, optimized throughput, and a scalable cyber‑physical backbone that future‑proofs your factory for the next era of manufacturing.

We start by understanding your operational challenges and business goals through structured discovery workshops with stakeholders. Applying a design thinking framework, our team analyzes process inefficiencies, data blind spots, and automation opportunities. We then evaluate multiple solution pathways and recommend the most suitable technologies — whether IIoT, advanced analytics, ERP/MES integration, digital twins, or cloud manufacturing platforms — to deliver measurable performance improvements.

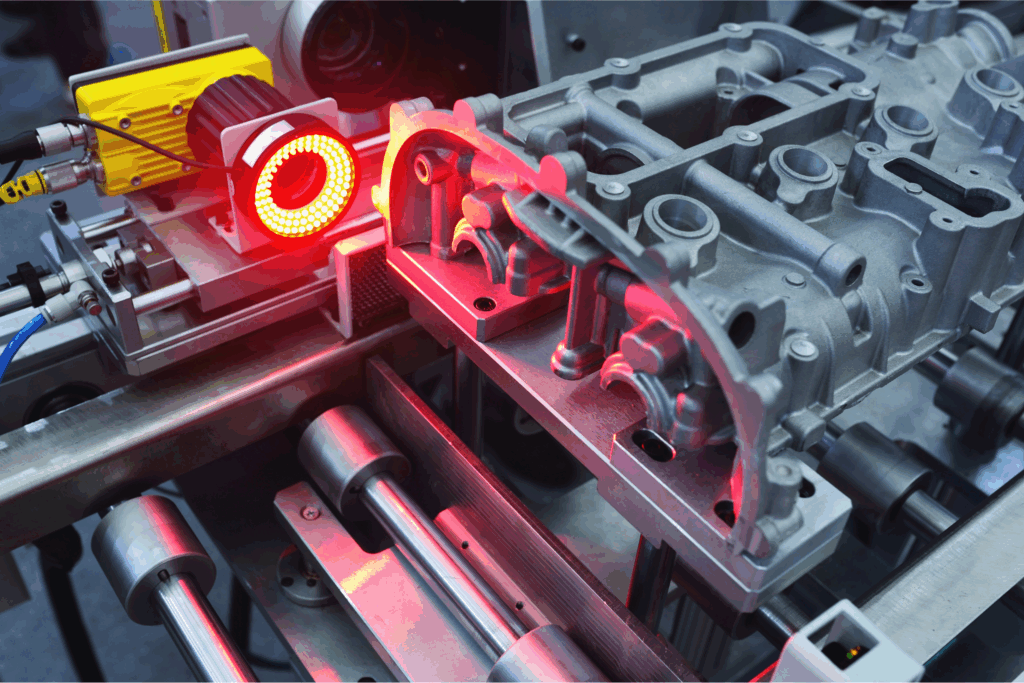

We build complete IIoT ecosystems that connect machines, sensors, control systems, and edge devices to centralized monitoring platforms. From selecting and provisioning industrial‑grade hardware to deploying edge computing or cloud‑based data infrastructure, we ensure secure, real‑time data acquisition, processing, and visualization across your shop floor. This integration empowers predictive maintenance, production optimization, and energy efficiency.

We automate repetitive, high‑impact workflows across both physical production lines and digital operations. This includes configuring real‑time machine triggers, automated alerts, and data‑driven approvals that improve speed, reduce errors, and standardize processes. Our automation frameworks leverage M2M communication protocols (OPC‑UA, MQTT) to ensure seamless interoperability and eliminate manual intervention wherever possible.

Our delivery covers end‑to‑end hardware and software deployment, including sensor installation, PLC/DCS programming, control panel integration, and the configuration of dashboards, databases, and ERP/MES interfaces. We handle every stage — from procurement and setup to functional testing and full‑scale deployment — ensuring that every hardware component and software module works together as a unified, cyber‑physical Industry 4.0 ecosystem.

Future‑ready factories aren’t built with yesterday’s tools. TreadBinary integrates the latest advancements in industrial technology to ensure your Industry 4.0 implementation remains competitive, secure, and scalable for years to come. Our approach blends operational technology (OT) and information technology (IT) with a clear focus on performance, agility, and continuous innovation.

We develop high‑fidelity digital replicas of machines, production lines, and entire facilities that allow you to simulate real‑world scenarios in a risk‑free environment. With these virtual models, manufacturers can test process changes, forecast equipment wear, and validate production schedules before making physical adjustments. This reduces trial‑and‑error downtime, improves maintenance planning, and accelerates continuous improvement initiatives.

We design hybrid architectures that combine edge computing for ultra‑low‑latency, on‑site decisionmaking with cloud manufacturing platforms for enterprise‑wide data storage, analytics, and scalability. Critical shop‑floor actions such as equipment safety shutdowns or quality rejections are processed locally for speed, while aggregated data is pushed to the cloud for long‑term analysis, AI/ML training, and centralized visibility across multiple sites.

Our AI and machine learning integrations continuously analyze sensor data, machine logs, and operational metrics to detect early signs of equipment degradation or process anomalies. Predictive maintenance models can accurately forecast failures, schedule interventions during planned downtime, and extend asset life. For quality control, computer vision and AI algorithms identify defects in real‑time, reducing scrap rates and enhancing product consistency.

With AR‑enabled devices and headsets, maintenance teams gain hands‑free access to step‑by‑step visual guides, annotated overlays on live machine views, and remote expert collaboration in real‑time. This shortens repair cycles, reduces dependence on senior technicians for every intervention, and ensures uniform service quality across geographies.

We implement centralized, high‑capacity data lakes that consolidate inputs from IoT devices, MES, ERP, quality systems, and production databases. This unified data environment enables advanced analytics, cross‑plant performance benchmarking, AI/ML training, and predictive modeling — unlocking actionable insights that traditional siloed systems cannot deliver.

Our Industry 4.0 solutions are built with security‑first principles. We deploy industrial‑grade firewalls, network segmentation, intrusion detection systems, and encrypted communication protocols like OPC‑UA and MQTT over TLS. Continuous threat monitoring and vulnerability assessments ensure your connected operations are protected from both external cyberattacks and internal misuse, safeguarding uptime and intellectual property.

We deliver end‑to‑end Industry 4.0 solutions — from initial plant assessment and solution design to hardware deployment, system integration, and go‑live. Our methodology ensures every sensor, PLC, dashboard, and analytics tool works seamlessly as part of a unified, future‑ready ecosystem.

Optimize throughput, reduce waste, and unlock revenue streams with digitally connected operations.

Automate shop-floor processes and decision loops through real-time data and integrated control systems.

Enable AI, IoT, and smart analytics to transform traditional operations into intelligent, adaptive systems.

Mitigate disruption, boost resilience, and ensure operational continuity with expert-driven governance.

Real-time monitoring, energy management, and production automation across discrete and process manufacturing.

Predictive maintenance, quality tracking, line balancing, and visibility across assembly and logistics.

Connect CNCs, fabrication lines, and control panels for live performance tracking and downtime analysis.

Monitor loom runtime, track consumption, and reduce wastage with IoT-ERP integration.

Enable compliance and traceability with real-time batch tracking, temperature/humidity monitoring, and audit-ready logs.

Automate packaging lines, track throughput, and reduce material handling loss with live dashboards.

According to McKinsey, over 70% of manufacturing data generated on the shop floor is never analyzed or acted upon — leading to inefficiencies, avoidable downtime, and missed optimization.

Stay updated with TreadBinary’s latest milestones, partnerships, and initiatives — shaping industries and communities through innovation and responsibility.

Whether you’re optimizing existing systems or planning a complete transformation — our team is here to guide, build, and deliver.