Maximize Material, Minimize Waste, Save Time

hac is an intelligent, cloud-based cutting layout optimization software designed to maximize material utilization, minimize waste, save time, and accelerate production planning across metal, wood, glass, leather, and plastic industries.

Compatible with manual, semi-automatic, and automatic cutting processes.

Proven to reduce scrap by 40% and cut planning time in half.

Optimized for different types of material in one go. In addition to Metal, Glass, Wood, Leather, Stone

Patented algorithm utilizes raw-material intelligently to gives best optimized cutting plan

Smartly select raw materials based on requirement specifications and consumption strategies

Strategies like highest material utilization, least cutting time and minimal scrap generation to have best optimization

Complete visibility of stock consumption order fulfilment monitory quantification on micro level of layout and macro level of project

Generate periodic reports on Planner, Project, Plant & Group level to quantify sales, production, purchase along with scrap losses & reusable off-cuts

Get accurate project costing to offer competitive sales price to your customer

Use order quantities, raw material consumption, reusable parts report and trends for effective forecasting to grab price advantage while procuring

Whether it’s guillotine-style shearing, angled miter cuts, or complex contour nesting, hac handles it all with speed, precision, and optimization intelligence.

A guillotine cut is a precise, edge-to-edge, straight cut made across a rectangular sheet, often using a guillotine machine, which is a device with a large blade that descends to make the cut.

In cutting applications, the cut produces smaller, uniform rectangular pieces from a larger sheet, such as cutting glass, steel, wood, or cardboard.

A miter cut is an angled cut made across the face or width of a piece of material. It is used to create a miter joint, where two pieces of metal, wood or other material are cut at an angle and then joined to form a corner. The most common example is cutting two 45° angles to form a 90° corner.

Plan perfect angled cuts with auto-rotation, stock utilization, and scheduler logic.

A contour cut follows the specific outer or inner outline of a design, resulting in a custom, shaped cutout rather than a standard rectangular one. This computer-guided process uses a blade to precisely cut along the digital “contour line” of drawing.

Proven to reduce scrap by 40% and cut planning time in half.

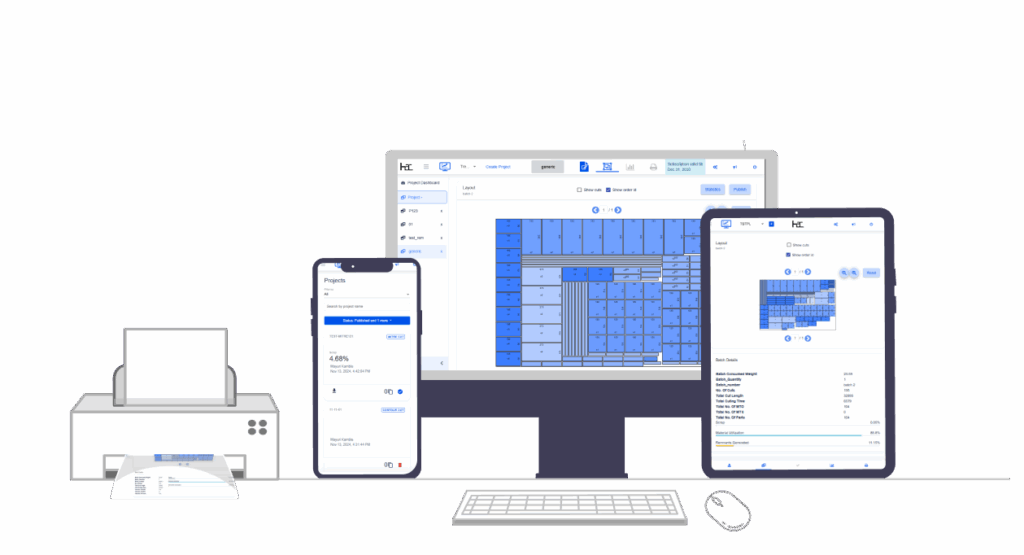

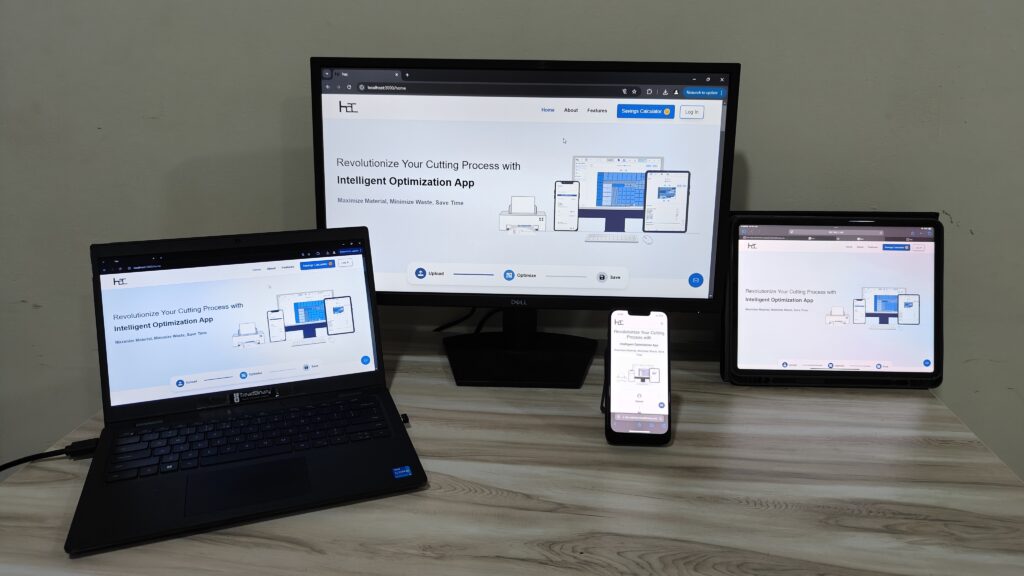

Built on patented technology, cloud-first, and designed for every device.

Intellectual property is protected using patent, which is recognized in 163 countries.

Access your account and details from any device or location on your device across the globe.

Application made so easy that cutting planning can be done within few intuitive clicks.

Any device with decent internet connectivity be it laptop, desktop, cellphone, tablets can be used to run this application.

Trusted by manufacturers across sectors — from automotive to aerospace.

Join manufacturers worldwide who’ve cut scrap by 40% and boosted output.

Trusted by 100+ industrial teams across 12 countries.

Our experts will walk you through hac’s features and show how you can reduce scrap and boost productivity.